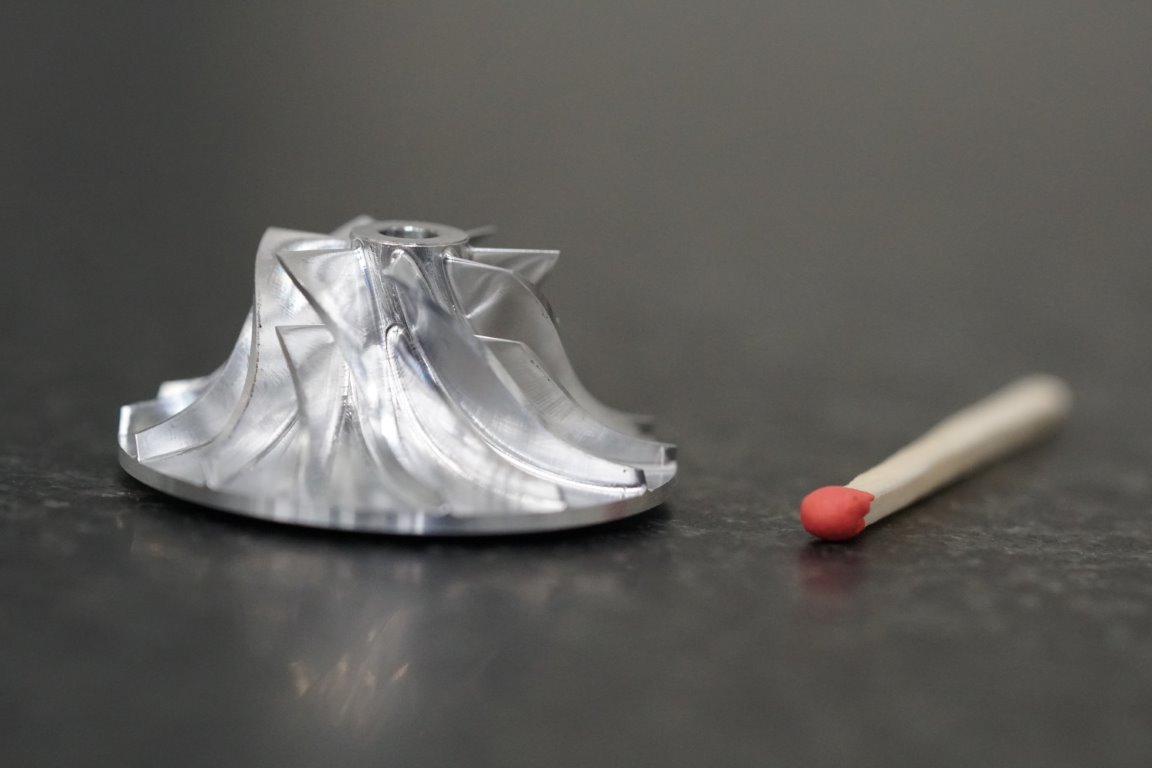

Unikatowa sprężarka

Serdecznie zapraszamy do zapoznania się artykułu na łamach Pulsu Biznesu, który opisuje projekt badawczy realizowany pod kierownictwem dr. Klonowicza, obecnego prezesa Zarządu Turbochill Sp. z o.o. Przejdź do artykułu

W naszej ofercie znajdują się bezolejowe i hermetyczne sprężarki oraz turbiny i turbogeneratory małej i średniej mocy.

Projektujemy i dostarczamy kompleksowe rozwiązania wysokoobrotowych sprężarek wirnikowych i turbin do zastosowań przemysłowych dla systemów chłodniczych, pomp ciepła, odzysku energii odpadowej, sprężania i ekspansji gazów procesowych.

Projektujemy, wytwarzamy i wdrażamy wysokoobrotowe, hermetyczne i bezolejowe maszyny wirnikowe małej i średniej mocy od kilku do kilkuset kilowatów, które znajdują zastosowania w takich urządzeniach jak układy chłodnicze, pompy ciepła, układy ORC, systemy sprężania gazów procesowych, układy odzysku energii z przepływających gazów.

Maszyny wirnikowe charakteryzują się szeregiem zalet w stosunku do urządzeń wyporowych (objętościowych), które tradycyjnie stosuje się między innymi w przemyśle HVAC&R.

Oprócz rozwijania nowych produktów specjalizujemy się w projektowaniu, analizie, optymalizacji i w badaniach urządzeń przepływowych, zarówno małoskalowych jak i przemysłowych oraz przeznaczonych do dużej energetyki.

Nasi inżynierowie posiadają bogate doświadczenie w takich dziedzinach jak mechanika płynów, wymiana ciepła, dynamika maszyn oraz wytrzymałość elementów konstrukcji. Ponadto, jako grupa tworząca przez wiele lat kadrę naukową, współpracujemy z polskimi i zagranicznymi uczelniami i instytutami naukowymi.

Turbochill Sp. z o.o. rozwija typoszereg innowacyjnych sprężarek odśrodkowych przeznaczonych do pracy w układach klimatyzacyjnych, chłodniczych oraz pompach ciepła. Sprężarki te, w przeciwieństwie do najpowszechniej stosowanych obecnie maszyn wyporowych, należą do grupy urządzeń wirnikowych, co ma wymierne i pozytywne przełożenie na cechy oraz koszty eksploatacyjne.

Tradycyjne maszyny wirnikowe były do niedawna domeną dużych urządzeń i instalacji procesowych. Mniejsze urządzenia, w zakresie kilki do kilkuset kilowatów mocy napędowej, charakteryzują się stosunkowo wysokimi prędkościami obrotowymi, co przekłada się na pewne wyzwania techniczne związane z łożyskowanie, technologią uszczelnień, silnikami napędowymi i sterowaniem. Dzięki zastosowaniu autorskich rozwiązań w dziedzinie aerodynamiki, łożyskowania gazowego i cieczowego oraz wykorzystaniu najnowocześniejszej energoelektroniki byliśmy w stanie sprostać tym trudnym konstrukcyjnym wyzwaniom.

Serdecznie zapraszamy do zapoznania się artykułu na łamach Pulsu Biznesu, który opisuje projekt badawczy realizowany pod kierownictwem dr. Klonowicza, obecnego prezesa Zarządu Turbochill Sp. z o.o. Przejdź do artykułu

Turbochill pospisał umowę inwestycyjną z Funduszem VC Link na wsparcie w rozwoju innowacyjnej, bezolejowej sprężarki do zastosowań w branży HVAC&R.

Gorąco polecamy film z badań ruchowych turbiny przeznaczonej do siłowni ORC, którą nasz zespół zaprojektował dla firmy Marani Sp. z o.o., naszego wieloletniego partnera, który wprowadził do swojej oferty układy